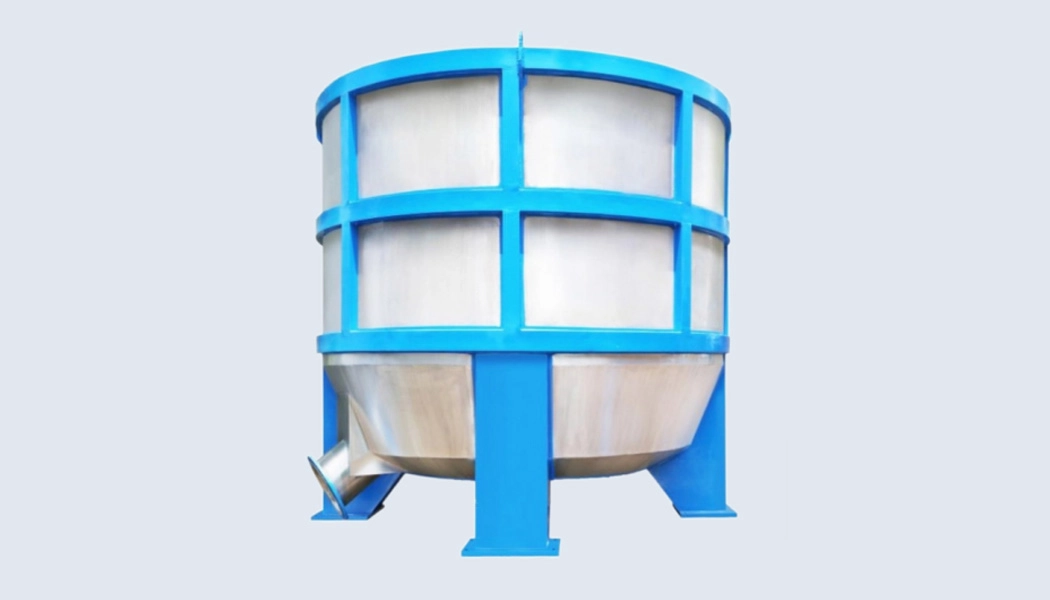

Hicon Pulper

LET’S START WORK TOGETHER

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

- +91-85588-88884

- mail@harjitpapermachinery.com

Characteristics

- HICON pulper is a High Consistency Pulper This type of pulper is equipped with the de-trasher system.

- HICON pulper operates at consistency 12-16% The special helical screw type design of rotor provides high capacity & low power consumption.

- It is suitable for slushing of recycled & virgin pulp. This type of pulper is designed for efficient slushing of unsorted waste paper like printed papers, newspapers, laminated kraft, brown grade kraft, wet strength paper, etc. It aiso serves for detaching the ink from printed papers.

- Provision for steam injection is given for raising the temperature of stock.

- The intense circulatory action of rotor provides homogeneous fiber stock quite suitable for deinking process ahead.

- The slushed stock then diluted to 4-5% consistency and then taken to the de-trasher which further disintegrate the chips and discharges accept through screenplate.

High Consistency Rotor:

- The rotor is designed in the form of helical screw having three flights.

- The rotor is designed into different sizes as per capacity of pulper.

- We provides cast cum fabricated rotor.

- All the flights are hard faced on working edges.

- Helps in low power consumption.

- The rotor is dynamically balanced.

- Easy to install & gives efficient slushing.

Benefits:

- It is a batch operation pulper normally with cycle time 25-30 minutes.

- The consistency obtained is 12-16%. Low power consumption.

- Pneumatically operated valves.

- Works in auto cycle with PLC panel.

- Lower consumption of steam & chemicals.

- No breaking up of contaminants due low peripheral speed of rotor and easy removal of contraries from stock.

- Due to the phenomena of fiber to fiber friction separates out the plastic from stock.